All you need are the speed RPM , number of flutes, material and tool diameter. If the material you need is not liste let us know and we can help you find the right speed and feed for your piece. You can also figure out the cut time in minutes based on the cut length and feed rate.

Materials have rated surface speeds for a given type of cutter. Feed Rate Calculator. How to calculate feed speed?

Onsrud bits are typically allowed a cut depth per pass equal to the cutting edge diameter unless otherwise specified. For a deeper cut, it will be necessary to reduce the chip load. This post should give you a head start. Even if you know the milling speed and feed formulas, it still takes a lot of time to work out the , especially when there are multiple cutting tools to select.

Chip Load per leading edge. The harder the material the slower the speed. Optimizing feed rates and speeds : 1. Start off using an RPM derived for the chip load for the material being cut (see charts). Increase the cutting speed ( feed rate) until the quality of the part’s finish starts to decrease or the part is starting to move from hold downs.

Then decrease speed by. Your calculator seems much better than what I have been doing but I was surprised at the result I got compared to the calculator I usually use. These calculations are based upon theoretical values and are only intended for planning purposes.

This RPM and IPM calculation formula for drilling can also used to figure out how long the cutting time would be in minutes for a given cut length. Free GDT Calculator ? The Haas control has features within the Calculator to help you quickly find these values without opening a tool catalog or going online to figure it out. Obviously all the wood machining inconsistencies listed above make decisions about feed rate and RPM more difficult than metalworking. Turning operations remove material from a rotating workpiece by feeding a single-point cutting tool axially, along the side of the workpiece.

Where chipload is the amount of material cut per tooth (feed per tooth). Click the appropriate link below, to download a copy of the calculator. I am creating a new calculator based on your feedback. Please fill out the form below with feeds and speeds that work for you and I will.

Calculate feed and speed parameters for mills, drills. Speed Improvements v1. Equations and Explanation Behind this Calculator This calculator will determine speeds and feed rates for machining operations on mill or lathes.

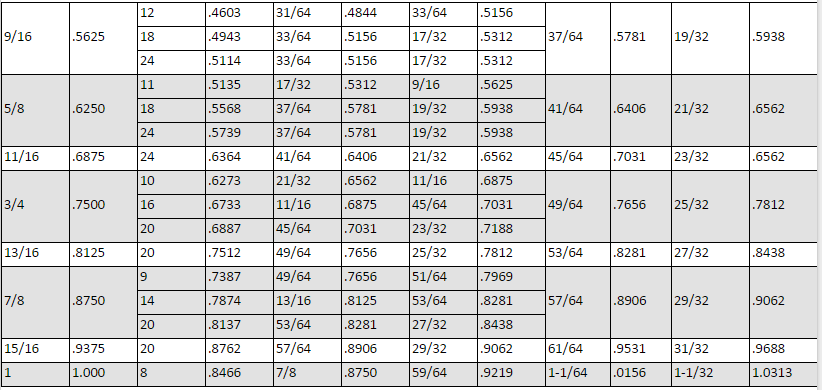

Cutting speeds are usually given in feet or meters per minute and these speeds must be converted to spindle speeds , in revolutions per minute, to operate the machine. CNC Programming Services. The document has moved here.

For deep slots reduce the Ft. Convert values shown between Inch and Metric measurements. Thanks to our friends at custompartnet. Xometry is now a one-stop shop for milling, drilling and turning calculators.

Result will be the feed rate in inches per minute. Please include as much information about the material you are machining as possible. Spindle Wattage is Monitored and Warnings Reported Against Programmed Limits.

Please understand that feeds and speeds depend on many factors and it is your responsibility to make sure that the values calculated by the calculator do not inflict damage on your machine or hurt people. These will need adjusting depending on specific machining conditions. Rigibore accepts no liability for the information provided on this page, select a tab below to begin.

This reference tool is designed to help you estimate cutting times and blade speed and feed for a range of metals. Heat kills the cutting edge in any material. If you are getting a burnt edge anywhere, kick up the feed rate (IPM).

Some machines slow down on radius cuts due to the calculation speed of the processor. You may need to increase the feed in the radius cuts. Or slow down the RPM to match the speed loss - this will help tool life. Bottom lead or Spiral flute taps are used.

Thread depth ( ) increase.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.