At Finance, you get free stock quotes, up-to-date news, portfolio management resources, international market data, social interaction and mortgage rates that help you manage your financial life. View real-time stock prices and stock quotes for a full financial overview. SMM = surface meters per minute. Radial Depth of Cut in Percentage of Diameter.

CLF = chip load factor. Cutting speed recommendations. For AD equal and above Tool Dia. Feed at Suggested Value. This is a safe and secure way to access Saint Francis Healthcare System providers and services — all day, every day.

It allows you to create and count on a convenient, valuable health connection for you and your family. Resulting Revolutions Per Minute: RPM. Surface Feet Per Minute: sfm Calculate. Find the latest Sprouts Farmers Market, Inc.

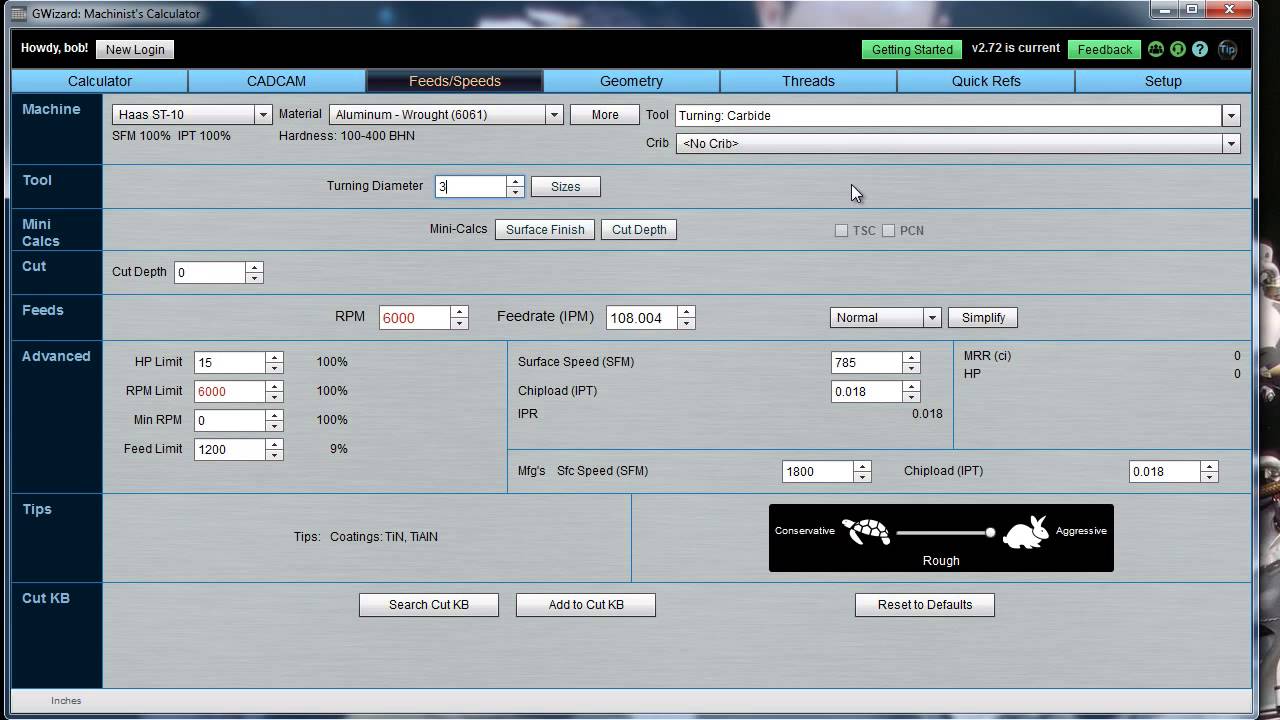

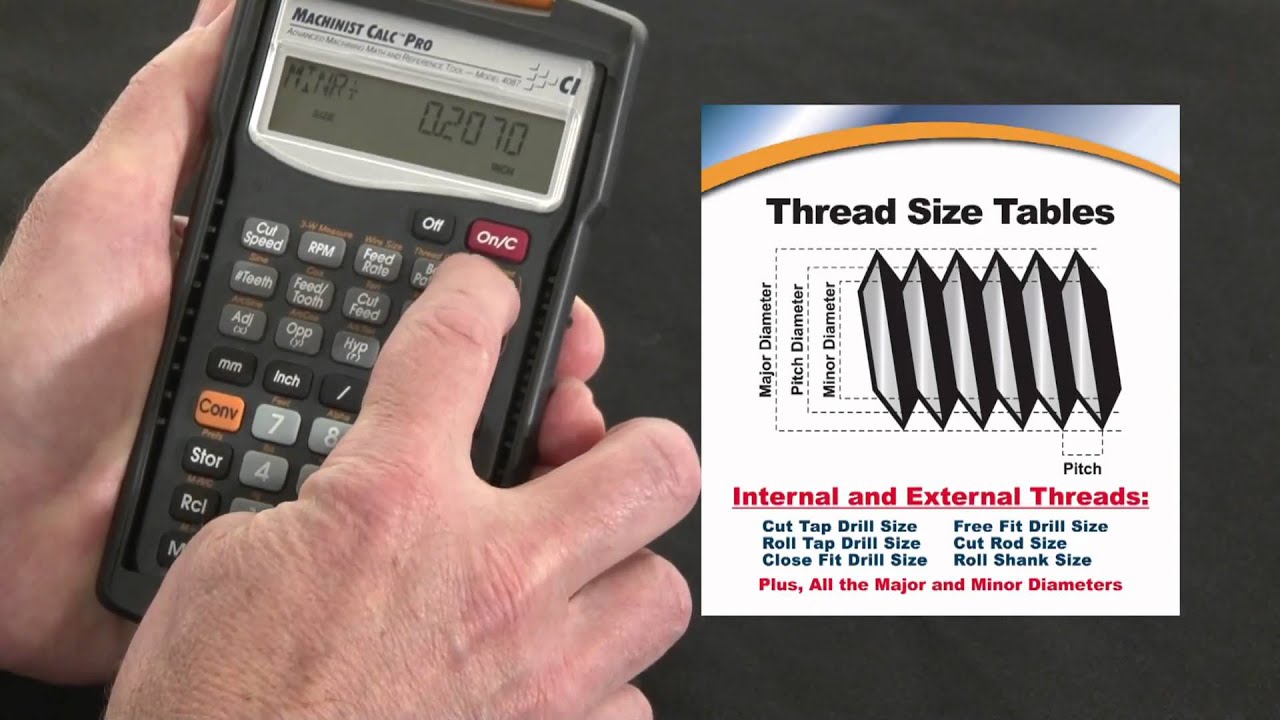

Metric To Inches: mm per rev or mm Calculate. Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Please include as much information about the material you are machining as possible.

Starting parameters only. Length-to-diameter ratios, setup, and machine rigidity may affect performance. Check machinability rating of the material to be machined and adjust First Pass Depth. The conversion chart is not that big of deal since its an easy calculation, but it is nice to have. SFM to RPM Calculator.

High Speed Steel Reamers. If surface finish is the priority use IPT from table with no adjustment for chip thinning. Click here to download a printable PDF file of this chart.

Headquarters: Granby Street. White chips indicate speed should be increased. For lighter cuts use higher range of recommended SFM. For greater radial cut use lower range of recommended SFM. Extra long end mills, FPT should be reduced by.

Below the material size is the suggested tooth pitch for that material size. Beneath tooth pitch, the chart lists the blade speed and cutting rate for each type of material size. Assistant Division Director. Organizational Charts.

Office of the Director. Reduce RPM or ensure adequate supports are in place or use an intermediate length gun drill. Bottom lead or Spiral flute taps are used. The answer is a speeder hea which depending on the brand and model, can easily achieve spindle speeds of 50rpm or higher (often way higher).

Drilling operations are those in which a cutting tool with sharp teeth, such as a twist drill, rotates and feeds into the workpiece axially, forming a hole with a diameter equal to that of the tool. Thread depth ( ) increase.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.